Product Description

Rod Mill

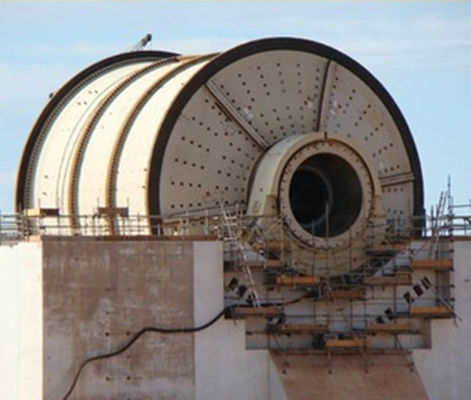

ZTIC can produce cylinder diameter below 8m rod mills. The rod mill is used for primary ore grinding in manual stone sand, ore dressing, chemical industry, electric power and other industries.We have first-rate rod mills research and design team, perfect test and inspection means and excellent rod mills manufacturing equipment and manufacturing technology, and have formed a completerod rod mill experimental research, design, manufacture, detection and service system.

Rod mill [1] is a mill in which the grinding body in the barrel is a steel rod.Rod mill is generally wet overflow type, can be used as a level open grinding, widely used in artificial stone sand, mineral processing plants, chemical plants in the power sector of the level grinding.The mill is mainly composed of the motor, the main reducer, the transmission part, the cylinder part, the main bearing, the slow transmission part, the feeding part, the discharging part, the annular seal, the thin oil lubrication station, the large and small gear jet lubrication, the base part and so on.The main reducer has parallel shaft and hard tooth surface.Rod mill is asynchronous motor through the gear reducer and small gear coupling, turns around the big gear reduction, directly driven rotary rotary, barrel inner is equipped with the appropriate grinding medium - steel rods, grinding medium under the action of centrifugal force and friction force, to manufacture materials by feeding continuously into the barrel inside, are controlled by the movement of grinding medium crushing,And through the overflow and continuous feeding force of the product out of the machine, in order to proceed to the next stage of processing.The working principle, structure, type, grinding medium, application, installation and matters needing attention in installation are introduced in detail.

Rod mill

Rod Mills Model:

Rod Mills:φ1.5x3.0~φ4.0x7.0m,Effective Volume 4.6~60.7m3;

Coal water slurry Rod Mills:ø3.2x4.5~φ4.0x6.7m,Max .Effective Volume 77.6m3;

Capacity:5-150 tph

Rod mill

The preparation of ball or pebble mill feed is an important application for CITICIC's rod mills.

The preparation of ball or pebble mill feed is an important application for CITICIC's rod mills. These mills produce a uniform-sized product while minimizing the production of tramp oversize and unwanted fines.

The rod mills accept a feed size up to 2" and produce a typical product size of 5 to 10 mesh when operating in open circuit and as fine as 35 mesh in closed circuit with a screen or other sizing device.

Rod mills Applications

The rod mill, a tumbling mill characterized by the use of rods as grinding media, is used for grinding ores, coal/coke, and other materials for both wet

and dry applications. The rod mill performs best when making products having a top size of 4 mesh to 16 mesh operating in open circuit, or as fine as 35 mesh operating in closed circuit with a screen or other sizing device. The rod mill accepts feed ore as coarse as 1 1/2” top size although better performance is obtained by restricting ore feed size to 3/4”.

Materials too wet for fine crushing and dry screening may be wet ground in a rod mill. Practice has demonstrated the ability of a rod mill to dry grind damp materials that will pack or plug other grinding equipment. and scrap loss are reduced by correct selection of liners for the specific grinding duty. Additional

benefit results from use of a backing material, such as rubber between the liners and the mill shell.

Feature

The cylindrical mill adopts the driving type edge-driving, center-driving, edge-driving with multi-point meshing, etc; driven by asynchronous motor +reducer +pinion and gear as well as synchronous motor + air lclutch + pinion and gear.

Generally supported by static-dynamic pressure bearing on both ends. Fuuly closed self-aligning 120º osculation rocker bearing is used. Also single or double slipper staic- dynamic bearings can be used. The bush is made by NC machine.

The large open gear is designed using AGMA standard, Equipped with reliably sealed gear housing and grease ahtomatic spraying lubrication system.

The shell is key part of a mill. Carry out finite element analysis on it with computer to ensure the reliable operation;

The shell is automatically welded, ultrasonic inspected, wholly annealed and machined by large special machine tools on one chucking; there special seal on static-dynamic connection parts , ch as feed and discharge hoper, trunnion, etc, to prevent oil and slurry leakage;

The liner is of wear-resistance material mad by our company, wich has been specially heat-treated, with high hardness and long service life. Also other wear-resistance casting or rubber liner can be used;

There are slow speed drive for medium and large mill;

The high and low pressure lubricating station is equipped for medium and large mill;

The control and protection system is controlled by PLC.

Wet Grinding Rod Mills

Historically, rod mills have been used as the first grinding stage after crushing in mineral benefici ation circuits. The rod mill product was further ground in ball mills before separation of valuable minerals from the host rock. With the advent of semi-autogenous (SAG) mills replacing secondary and tertiary crushing as well as first stage grinding,the rod mill has fallen out of favor for new large mineral beneficiation circuits.

A recent application for a trunnion overflow rod mill is in the preparation of coal and petroleum coke slurries for Integrated Gasification Combined Cycle electric power generation and co-generation

facilities. The relatively coarse open circuit rod mill product, plus the ability to not generate excess fines, is key to making a high percent solids, low viscosity slurry capable of being pumped directly into the gasification reactor vessel. This service has been proven to be an excellent application for the traditional design rod mill.

Dry Grinding Rod Mills

End peripheral discharge rod mills are used most frequently for dry grinding operations. Grinding damp materials to moderately coarse products in open circuit is feasible by using hot air, inert gas,or combustion gases to air-sweep the rod mill.A recent new application for the end peripheral discharge rod mills has been the preparation of fuel for Circulating Bed Boilers (CFB). It is critical to have a coarse product with the fewest amount

of fines for this product as the fuel mass must be fluidized by combustion airflow. This same airflow will elutriate excess fines from the fuel mass be-fore combustion is complete and reduce boiler efficiency through loss of the fuel fines with the ash.

Rod Mill Main Technical Parameters:

| Model |

Cylinder Diameter

(mm) |

Cylinder Length

(mm) |

Effective Volume

(m3) |

Mill Speed

(r/min) |

Load of grinding media (t) |

Electromotor |

Size

(L×W×H )

(m) |

Weight

(T)

|

Motor power

(kW) |

Speed

(r/min) |

| MB15×30 |

1500 |

3000 |

5 |

23 |

8 |

75 |

743 |

7.6×3.4×2.8 |

20 |

| MB17×30 |

1700 |

3000 |

5.8 |

20 |

10.2 |

90 |

980 |

7.6×3.5×3.1 |

40.4 |

| MB21×30 |

2100 |

3000 |

8.8 |

19.4 |

25 |

220 |

735 |

8.7×4.8×4.4 |

48 |

| MB21×36 |

2100 |

3600 |

10.8 |

21 |

28 |

220 |

735 |

9.5×4×4.7 |

52.5 |

| MB24×30 |

2400 |

3000 |

11.8 |

18.2 |

27 |

250 |

735 |

8.5×4.2×4.6 |

58 |

| MB27×36 |

2700 |

3600 |

18.8 |

17.5 |

42 |

400 |

187 |

12×5.7×4.7 |

70 |

| MB30×40 |

3000 |

4000 |

25.9 |

16.2 |

50 |

500 |

187 |

12.6×6.1×4.9 |

89 |

| MB32×45 |

3200 |

4500 |

33 |

15.5 |

56 |

630 |

167 |

16×8×5.6 |

111.5 |

| MB32×48 |

3200 |

4800 |

34 |

15.5 |

60 |

710 |

740 |

12×7×6 |

121.2 |

| MB36×54 |

3600 |

5400 |

50 |

14.5 |

97 |

1000 |

167 |

16×8×6.7 |

155 |

| MB38×52 |

3800 |

4200 |

54.1 |

14.2 |

102 |

1120 |

992 |

15×8.27×6.21 |

175 |

| MB38×58 |

3800 |

5800 |

60.3 |

14.2 |

112.2 |

1250 |

167 |

15.6×8.27×7.21 |

156 |

| MB40×60 |

4000 |

6000 |

70 |

14.0 |

130 |

1400 |

200 |

18.2×9.00×7.5 |

163 |

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.

Aftersales service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!