Mill Liners Ball Mill Liners SAG/AG Mill Liners Rod Mill Liners MATERIALS INTRODUCTION

Ball mill lining plate is used to protect the cylinder body, so that the cylinder body from the direct impact and friction of the grinding body and materials, but also can use different forms of lining plate to adjust the motion state of the grinding body, to enhance the grinding effect of the grinding body on the material, help to improve the grinding efficiency of the mill, increase output, reduce metal consumption.

| item |

sescription |

| ball mill liner |

mn13cr2 |

| cement mill liner |

mid chrome steel |

| AG MILL AND SAG MILL LINE |

LOW CARBON ALLOY STEEL |

Ball mill lining plate is used to protect the cylinder body from the direct impact and friction of the grinding body and materials, but also can use the characteristics of editing speech

1. High abrasion resistance and impact resistance

Through scientific and reasonable alloying element formula, the alloy steel lining plate in the double medium quenching has good physical and chemical properties, hardness HRC45-55 above, impact toughness value 25J above, and service life is more than 2 times that of high manganese steel.Able to withstand tremendous impact force.It can keep the surface shape of the lining board for a long time in order to ensure that the mill can increase the output by more than 5% stably.

China's current general wear resistant material series of high manganese steel series: such as high manganese steel (ZGMN13),

High manganese alloy (Zgmn13Cr2MoR), ultra-high manganese alloy (Zgmn18Cr2MoR), etc.

High manganese steel (such as ZGMN13) under severe impact or contact stress, its surface will rapidly harden, while the core still maintains a strong toughness, hard outside and tough inside both wear resistance and impact resistance.And the heavier the impact on the surface, the more full the surface hardening, the better the wear resistance.Because the hardness of high manganese steel itself is very low (HB170-230), the wear resistance is extremely limited before hardening. If the surface of high manganese steel is not enough to bear the impact force, the surface can not be fully hardened (after full hardening, the surface hardness can reach HB550 or below, otherwise), then the wear resistance will not play a role, and the wear resistance will not be shown.

Because Zgmn18Cr2 contains more manganese, the surface hardening can be more sufficient, so more wear-resistant.

Of course, ZGMN18Cr2 series (such as ZGMN18Cr2MORE) is also more expensive than ZGMN13 series.

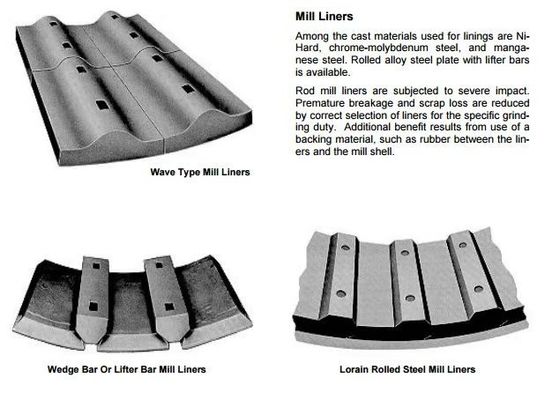

Mill Liners:Ball Mill Liners, SAG/AG Mill Liners, Rod Mill Liners type description

GENERAL DESCRIPTION

Grinding wear parts are subjected to different combinations of impact and abrasion, as they are used in SAG/AG, ball or rod mills. Our wear parts are manufactured to the highest standards of quality, traceability and delivery, ensuring high levels of reliability for our customers. Also, our wear parts add value to customers’ processes through customized designs.

SAG/AG Mill Liners:

• Integrated and/or plate and lifter designs for head and shell liners

• Grates

• Pulp lifters

• Filler rings

Ball Mill Liners:

• Single wave liners

• Modified single wave liners

• Double wave liners

• Shell liners

• Feed head liners

• Discharge end liners

Rod Mill Liners:

• Shell liners

• Head liners

• “Wedge” shell liners

Steel Shell Mill Liners for AG Mill

Low Carbon Martensite Mill Liners

High Manganese Steel Mill Liners

Alloy Steel Mill Liners

The main material in the hammer of high manganese steel is high manganese steel (Mn13,Mn13Cr2 and Mn18Cr2). With the continuous development of wear-resistant materials, the high toughness of high manganese steel is incomparable to other wear-resistant materials.v

ZTIC specialized in producing wear-resist castings used in grinding equipments and main spindle bush, brake shoe for the mill of various specifications. It has strong casting, heat treatment and machining ability, strict quality and process controlled methods as well as the perfect examination and experimental means, so that can wear-resisting products enjoy high reputation in China and sells well all over the world.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!