High capacity Laboratory ball mill efficient fine powder grinding machine

ZTIC has produced cement grinding mills fitting the requirement of cement industrial development with cement design institutes in Tianjin, Nanjing and Hefei for dozens of years. Our large cement grinding mills have been sold in many domestic cement manufacturers, and exported to Vietnam, Indonesia, Rwanda and other countries. We have first-rate cement grinding mill research and design team, perfect test and inspection means and excellent large Cement Ball Mill manufacturing equipment and manufacturing technology, and have formed a complete Cement Ball Millexperimental research, design, manufacture, detection and service system.

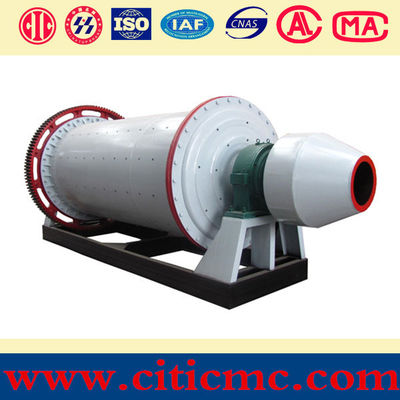

Introduction of ball mill

Ball mill is the key equipment to crush the material after it is broken.

Ball mill is one of the high fine grinding machinery widely used in industrial production. There are many kinds of it.

Such as tube ball mill, bar ball mill, cement ball mill, ultra-fine laminating mill, hand ball mill, horizontal ball mill,

Ball mill bush, energy saving ball mill, overflow type ball mill, ceramic ball mill, grid ball mill

Ball mill is suitable for grinding all kinds of ore and other materials, is widely used in mineral processing, building materials and chemical industries, can be divided into dry and wet grinding methods.It can be divided into two types, grid type and overflow type, according to different discharging modes.According to the shape of the barrel, it can be divided into four kinds: short barrel ball mill, long barrel ball mill, tube mill and cone mill.[1]

Cement mill is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement mill is not only suitable for over-flow grinding, but also applicable for cyclic close-flow grinding together with powder collector.

Laboratory ball mill

Ball mill is an efficient tool for fine powder grinding. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. Ball mill is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry way and the wet way. It can be divided into tabular type and flowing type according to different expelling mine.

Feature of Laboratory ball mill:

♦The cylindrical mill adopts the driving type edge-driving, center-driving, edge-driving with multi-point meshing, etc; driven by asynchronous motor +reducer +pinion and gear as well as synchronous motor.

♦Generally supported by static-dynamic pressure bearing on both ends. Fuuly closed self-aligning 120º osculation rocker bearing is used. Also single or double slipper staic- dynamic bearings can be used. The bush is made by NC machine.

♦ The large open gear is designed using AGMA standard, Equipped with reliably sealed gear housing and grease ahtomatic spraying lubrication system.

The shell is key part of a mill. Carry out finite element analysis on it with computer to ensure the reliable operation;

♦The shell is automatically welded, ultrasonic inspected, wholly annealed and machined by large special machine tools on one chucking; there special seal on static-dynamic connection parts , ch as feed and discharge hoper, trunnion, etc, to prevent oil and slurry leakage;

♦The liner is of wear-resistance material mad by our company, wich has been specially heat-treated, with high hardness and long service life. Also other wear-resistance casting or rubber liner can be used;

♦ There are slow speed drive for medium and large mill;

♦The high and low pressure lubricating station is equipped for medium and large mill;

♦The control and protection system is controlled by PLC.

Laboratory ball mill technical advantages:

1. High capacity and Low consumption: the capacity of SCM series super-micro mill, compared with that of jet mill and mixing mill, has been improved by 40% under the same final fineness and electric power.

2. High fineness and Flexible adjustment: the final fineness can be adjusted from 325 meshes to 2500 meshes according to the requirements, and the fineness can reach D97≤5um.

3. Trustworthy security: there is no rolling bearing and bolt in the mill chamber, therefore, the bearing and sealing elements will not wear out easily, and the bolts will not loose to make damage to the equipment.

4. Clean and environment-friendly: equipped with the pulse filter and sound absorber, the mill reaches the environment-friendly standard of our country and reduces the dust and noise greatly.

Laboratory ball mill working principle

Large materials are crushed by Jaw crusher to the needed sizes firstly, then the materials are elevated to storage hopper by bucket elevator, third, the materials are fed into the grinding chamber for grinding by vibrating feeder equably and continuously. The powder after grinding goes upwards together with the airflow, after separating by powder separator, those which can meet the fineness requirement enters into the cyclone powder collector through pipe together with the airflow, and then discharged from the discharge valve as final products. The airflow is sucked into centrifugal blower through wind recycling pipe at the upper part of cyclone powder collector. The mainframe is driven by the speed reducer through the central axis in the mill.

The quincunx stand connected with the upper part of central axis, at the quincunx stand, rollers are set and by which the vibrating pivot formed. Below the quincunx stand and rollers there is shovel system. Materials are fed into the space between rollers and shovels when they are turning, and then be grinded by the pressure produced when rollers are turning, thus powder is made.

Laboratory ball mill | Technical parameters

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!