Micro Powder Production System Ore Grinding Mill High Efficiency Low Consumption

1. Basic introduction of micropowder mill

The main motor of the micro-powder mill drives the main shaft and each layer of turntables to rotate through the reducer, and the turntable drives dozens of ring rollers to roll and rotate freely in the grinding ring raceway through the pin.

The large material is crushed into small particles by the hammer crusher and then sent to the storage bin by the elevator. The electromagnetic vibrating feeder evenly sends the material to the middle of the upper turntable, and the material is scattered to the periphery of the circle under the action of centrifugal force. The material falling into the raceway of the grinding ring is punched, rolled, ground and pulverized by the ring roll. After the first layer is pulverized, the material falls into the second layer and the third layer. Ultrafine powder, the external air is sucked into the machine by the suction action of the high-pressure centrifugal fan, and the coarse powder after the third layer pulverization is brought into the classifier.

The vortex generated by the rotating turbine in the powder separator makes the coarse particles fall back for regrinding, and the fine powder enters the cyclone powder collector with the airflow and is discharged from the discharge valve at the bottom of the powder separator, which is the finished product. After being purified by the pulse dust collector, it is discharged through the fan and the muffler.

2.Ore grinding mill technical parameters

| Model |

Grinding Cavity Diameter

(mm)

|

Grinding Wheels and Roller Tables |

Maximum Feed Size

( mm )

|

Finished Fineness

(Number)

|

Capacity

(kg/h)

|

Power(kw) |

Dimension

(L×W×H)

(m)

|

Weight(kg) |

| Number of Grinding Rollers |

Number of Roller Tracks |

Mainframe |

Granularityum |

Number |

Mainframe |

Powder Separator |

Draught Fan |

| HGM60 |

600 |

15 |

3 |

≤10 |

5-45 |

3250-300 |

350-2500 |

37 |

11 |

30 |

10×2×5.5 |

5900 |

| HGM80 |

800 |

21 |

3 |

≤10 |

5-45 |

3250-300 |

600-4000 |

55 |

18.5 |

45 |

11.9×2.7 ×5.8 |

7800 |

| HGM100 |

1000 |

27 |

3 |

≤10 |

5-45 |

3250-300 |

900-6000 |

90 |

30 |

75 |

14.5×3.8 ×6.3 |

10500 |

| HGM1280 |

1280 |

44 |

4 |

≤10 |

5-45 |

3250-300 |

1200-8000 |

132 |

45 |

90 |

17.5×4.5 ×7.5 |

15000 |

3. Performance characteristics of micro-powder mill

(1) The micropowder mill has high efficiency and low consumption. In the case of the same material, power and finished product fineness, the output is 40% higher than that of jet mill and stirring mill;

(2) The micro-powder mill has a long service life. In the case of the same fineness of materials and finished products, it has a longer service life than the wear parts of impact pulverizers and turbo pulverizers, generally more than 1 year;

(3) There are no rolling bearings and no screws in the grinding chamber. There are no problems such as bearings, their seals and vulnerable screws that are easily loosened and damage the machine;

(4) The fineness of the products pulverized by the ultrafine mill can reach d97≤5μm at one time.

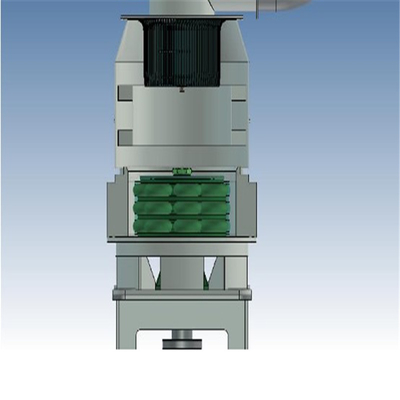

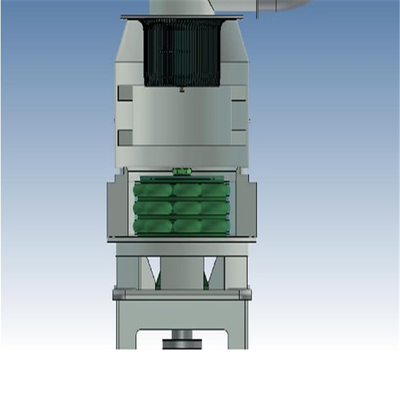

4.Ore grinding mill photo explanation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!