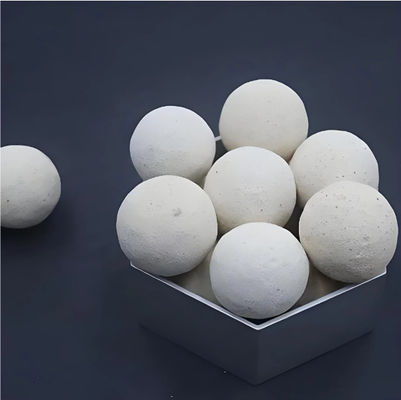

Environmentally Friendly Ceramic Balls For Mining And Ore Grinding

Brief Introduction

1. Mining ceramic ball is a special ceramic product used for mining and ore grinding. It is usually made of high purity ceramic materials, such as alumina or zirconia. Mineral ceramic balls have many superior properties, making them an important material in the field of ore grinding.

main characteristics

(1) High hardness: mineral ceramic ball has a very high hardness, can withstand high strength impact and wear, thereby extending the service life.

(2) Wear resistance: Due to its high hardness and wear resistance, the mineral ceramic ball can effectively resist wear during the ore grinding process and reduce the consumption of abrasive.

(3) High density: The mineral ceramic ball has a high density, which can provide higher grinding efficiency and better grinding effect.

(4) Corrosion resistance: mineral ceramic balls have good corrosion resistance to acids, alkalis and other chemicals, and can maintain stability in harsh ore grinding environments.

(5) Thermal stability: mineral ceramic balls can maintain stability at high temperatures without shape change or structural damage.

Mineral ceramic balls are widely used in the ore grinding process of mining, metallurgy, coal, electric power and other industries, common applications include ball mills, sand mills, vertical mills and other equipment. Their use can improve the efficiency of ore grinding, reduce energy consumption, and is environmentally friendly, because mining ceramic balls do not produce pollutants.

Product Parameters

| Parameter |

Typical value range |

| Materials |

Ceramic materials such as high purity alumina or zirconia |

| Hardness |

Mohs Hardness ≥9 |

| Density |

3.6 - 3.9 g/cm³ |

| Compressive strength |

2000 - 2500 MPa |

| Fracture toughness |

4 - 5 MPa·m^0.5 |

| Coefficient of thermal expansion |

6 - 8 × 10^-6/°C |

| Maximum service temperature |

1200 - 1500°C |

| Relative dielectric constant |

9 - 10 |

| Attrition rate |

<0.1% |

| Crushing efficiency |

>90% |

| Common shape |

Spherical, cylindrical, etc |

Product Display

After-sales service

LUOYANG ZHONGTAI INDUSTRIES able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

LUOYANG ZHONGTAI INDUSTRIES’s Field Service Engineers are trained specifically in the LUOYANG ZHONGTAI INDUSTRIES brand group products but are capable of undertaking the servicing of other OEM brands. Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time. LUOYANG ZHONGTAI INDUSTRIES also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Q&A

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time?

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms?

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!