Special Pearl Sand For Environmentally Friendly Dense Casting

Advantages of Mining Machine Spare Parts

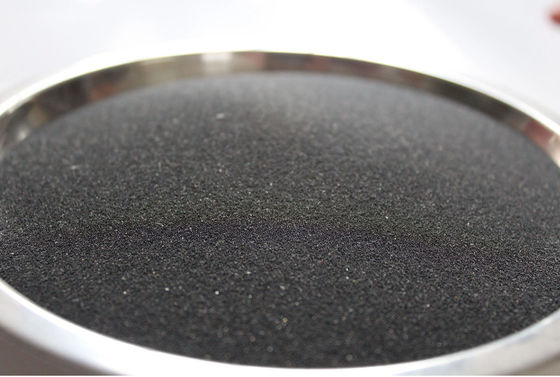

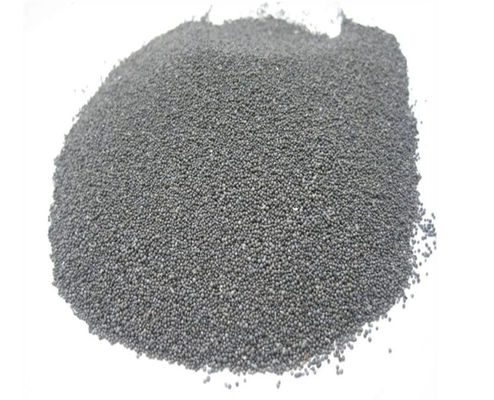

In the foundry industry, there are many complex tools that require pearl sand mold casting. However, the main raw materials for sand casting are widely available. There are various types of sand, and their properties and costs also vary. The cost of spherical sand in many sandstones is not very high, and its performance is also favorable.

Some experts suggest that pearl sand may become the main raw material for sand casting. As the raw materials of zircon sand are mainly in China, unlike chromite, the production of zircon sand is mainly in China, and the zircon sand used abroad must be purchased from China. Spherical sand is more suitable as a material for precision casting.

At present, the requirements for castings in China are diverse, and the materials for sand casting are also quite extensive. If the cost and quality requirements are not high, silica sand and sea sand can be chosen. If the requirements are higher, pearl sand can be mainly selected. Pearl sand can be mainly used for sand casting and is suitable for the use of medium and high-end sand.

In terms of casting advantages, the zircon sand manufacturer uses zircon sand entirely as filling sand for lost molds. The lost molds need to be compoured with materials that are heat-resistant, have good air permeability and are not prone to sand adhesion to cover the lost molds and combine them with zircon sand. With the disappearance of spherical sand, the sand mold will not be greatly affected, and spherical sand is also suitable for this work.

Production Process of Mining Machine Spare Parts

Select high-quality bauxite raw materials and place them in an electric arc furnace for melting. When the molten liquid flows out of the furnace, it is blown away by a compressed air flow. After cooling, spherical or nearly spherical particles with a smooth surface are obtained.

Product parameters of Mining Machine Spare Parts

| Model 1 |

Lost mold treasure bead sand |

30-40mesh |

40mesh |

30mesh |

10-30mesh |

10-20mesh |

8-12mesh |

| Model 2 |

Resin coated sand bao |

30-50mesh |

70-140mesh |

|

|

|

|

| Model 3 |

Polished pearl sand |

5-10mesh |

10-20mesh |

20-30mesh |

|

|

|

| Model 4 |

Drainage of pearl sand sand |

20-40mesh |

30-50mesh |

|

|

|

|

| Model 5 |

Cast steel pearl sand |

40mesh |

|

|

|

|

|

| Model 6 |

Paint treasure bead sand |

200mesh |

|

|

|

|

|

| Model 7 |

Treasure sand powder |

More than 200mesh |

|

|

|

|

|

Product Display Of Mining Machine Spare Parts

Q&A

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time?

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms?

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!