Compressive strength and wear resistance of petroleum fracturing proppants

Performance requirements for petroleum proppants: 1. The proppant must have sufficient compressive strength and abrasion resistance to withstand the intense pressure and friction during injection and effectively support the artificial fracture. 2. The proppant particles must have a low relative density to facilitate downhole pumping. 3. The proppant particles must not chemically react with the fracturing fluid or reservoir fluid at a temperature of 200°C, and the maximum allowable acid solubility must be less than 7%.

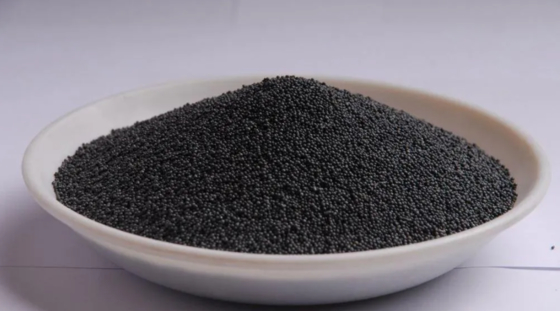

Currently, commonly used proppants include quartz sand, bauxite ceramsite sand, and resin-coated composite particles. Quartz sand is widely used due to its low cost and low density for easy pumping. However, quartz sand has low base strength and poor sphericity, which reduces fracture conductivity and makes it unsuitable for deep wells with high closure pressures. Composite particles made of resin-coated quartz sand offer improved sphericity, stronger corrosion resistance, and better conductivity. However, their short shelf life and high cost make them challenging to commercialize in today's cost-conscious world. Ceramsite proppants produced using the bauxite process offer high density, excellent sphericity, corrosion resistance, high temperature resistance, and high pressure resistance, all while maintaining cost control. Consequently, they are increasingly being adopted in oil and gas fields. Fracturing with ceramsite proppants has proven to increase well production by 30-50% and extend the service life of oil and gas wells. They are a key material for the development and construction of low-permeability oil and gas wells, increasing both production and service life.

Performance Requirements for Oil Proppants:

- Proppants must have sufficient compressive strength and abrasion resistance to withstand high injection pressures and friction forces, while effectively supporting artificial fractures.

- Proppants should have low relative density to facilitate pumping into downhole locations.

- Proppant particles should not undergo chemical reactions with fracturing fluids and reservoir fluids at temperatures up to 200 degrees Celsius, with a maximum allowable acid solubility of less than 7%.

Mining Machine Spare Parts

Mining Machine Spare Parts

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time:

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms:

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

Mining Machine Spare Parts

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!