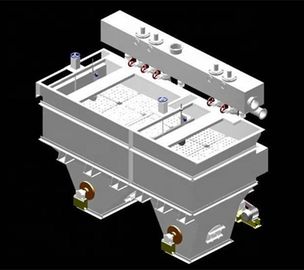

Ore Dressing Equipment Fixed sieve jig

The jig is a fixed sieve type, which is suitable for separating metal ores, such as tungsten and gold-bearing placer and tin concentrate. It can be used for separating fine and coarse materials. The maximum feed size is 6-8 mm, but in the case of separate placer, the maximum size is 12 mm.

The working principle of jig:

jig belongs to deep groove type selective equipment. All jigs have jig chambers. Acting mechanism and product discharging mechanism for agitating water flow movement. The sieve plate in jigging room is made of punched steel plate, braided iron screen or grate. When water enters the jigging room through the sieve plate, the bed should not rise very high and be slightly loose. The particles with high density enter the bottom layer because of local pressure and settling speed, while the particles with low density transfer to the upper layer. When the flow drops, the fine particles with high density can also enter the lower layer through the gradually compact bed clearance. The piston chamber is located at the side of the jigging chamber in the early years. The lower part is connected, and the eccentric connecting rod mechanism drives the piston up and down.

Jig beneficiation belongs to deep trough separation operation.

It uses water as beneficiation medium and uses the specific gravity difference of selected minerals in gangue to separate. Jig belongs to diaphragm type. The stroke and stroke can be adjusted flexibly according to the specific gravity of selected minerals. It is widely used in tungsten, tin, placer gold, red iron, brown iron, manganese, titanium and antimony. Gravity beneficiation of lead, tantalum and niobium.

There are many types of jigs.

AM30 jig belongs to large particle jig. It is widely used in gravity beneficiation of tungsten, tin, placer gold, hematite, brown iron, manganese, titanium, antimony, lead, tantalum, niobium and other metals. It can produce LTP34/2, LTA55/2, LTA1010/2, LTC-69/2, 2LTC79/4 and 2LTC-912/4 jigs according to user's requirements.

The trapezoidal jig 6109 has a capacity of 20-30T per hour.

Sawtooth wave JT1070-2 jig is widely used in tungsten, tin and gold because of its advantages of saving water, saving energy and improving the recovery of fine particles and minerals.

Extraction of metals from iron, manganese, titanium, technetium, chromium, sulphur and various alloy smelting slags.

LTA-1010/2 jig is mainly used for beneficiation of tungsten, tin and antimony ores.

LTP34/2 jig is widely used for jigging and beneficiation of heavy metals such as tungsten, tin, gold, iron, lead, zinc and manganese.

The double-bucket diaphragm jig can be divided into two types: the left jig and the right jig. The jig is a fixed sieve. It is suitable for separating metal ores, such as tungsten and gold-bearing placer, tin concentrate, etc. It can be used for separating fine and coarse materials. The maximum feed size is 6-8 mm, but in the case of separating placer, the maximum size is 12 mm.

Structure and instructions for use

The structure of LTS300 *450 double-bucket diaphragm jig consists of fuselage, transmission device, water separator, diaphragm and movable plug. The body has two hoppers of different sizes. Each diaphragm bucket is divided into jigging zone and diaphragm zone with an indefinite diaphragm. The jigging process is carried out by the agitation of the medium (water) caused by the reciprocating motion of the rubber diaphragm. The motor drives the big pulley to rotate through the triangular belt, so that the connecting rod on the eccentric axis moves up and down, and the rocker arm connected with the connecting rod also moves up and down. There are two connecting rods on the rocker arm to connect the rubber diaphragm, so that the diaphragm can get up and down reciprocating motion and jigging.

According to the particle size of the treated ore, the stroke of the connecting rod can be changed and different strokes can be selected to obtain the best jigging effect. The way to change the punch is to change the small belt pulley. There are two kinds of punches: 322 times per minute and 420 times per minute. Eleven different strokes (0-25.3mm) can be selected for loosening the fixed screw and nut, pulling out the positioning pin, rotating the eccentric adjusting sleeve and the relative position between the eccentric axis.

Because a sieve is added to the working sieve, the jig can be used to treat materials with uneven particle size. (Note: This screen can not be supplied according to the requirements of the order) After the raw ore is sent into the jig chamber, due to the drum action of the diaphragm, the ore particles are stratified according to specific gravity in the medium; fine and heavy ore particles are deposited in the upper and middle layers of the jig hopper through the gap and sieve hole of the artificial bed particles, and the coarse and light ore particles (minerals) are washed to the screen by the medium flow. Because the position of the rear jig chamber is 50 mm lower than that of the front jig chamber, the light ore particles overflow through the tail plate of the front chamber and enter the back chamber, which is jigged again. The position of tail plate can be adjusted according to the need to control the size of ore discharge. The concentrate in the storage bucket is discharged regularly by the discharge pipe.

Types of diaphragm jigs

Jigs can be divided into different types according to different standards, such as according to the location of diaphragm installation.

(1) Parallel diaphragm jig (e.g. LTP34/2 jig)

(2) Downward diaphragm jig (e.g. LTA1010/2 jig, JT1070/2 jig)

(3) Side-moving diaphragm jig (e.g. 2LTC-6109/8T jig)

| item |

remark |

| screen deck materials |

rubber, steel |

| screen type |

linear screen, circle vibrating screen |

Sawtooth wave jig specifications and detailed parameters are as follows:

Sawtooth wave jig is one of the key equipments for gravity beneficiation. It is widely used in non-ferrous metallurgical mines such as placer gold, tin, tungsten, lead, zinc, antimony, manganese, diamond, iron ore and other non-ferrous metallurgical mines and gold dredgers because of its large processing capacity, wide particle size range, high recovery and good effect. The JT4-2 and JT1.5-2 sawtooth wave large particle jigs in this kind of products can feed ore with a maximum particle size of 30MM, and are discharged through sieve-up and sieve-down. Applied to the beneficiation of barite, manganese ore, iron ore and other ores, it has the advantages of wide size range of ore feeding and remarkable reduction of water supply under sieve.

Traditional jigs are mostly driven by circumferential eccentricity, and their jigging pulsation curves are mostly sinusoidal waveforms. Because the rising and falling water flow speed and action time produced by diaphragm movement are basically the same, it is not conducive to loose jigging bed and ore particle stratification according to specific gravity, thus affecting the separation ratio and recovery rate of equipment.

Sawtooth wave jig is a kind of energy-saving gravity separation equipment developed and improved on the basis of traditional jig according to the stratification law of jig bed theory. Its jig pulsation curve is sawtooth, which makes the ascending water faster than the descending water: short ascending time and long descending time; it overcomes sinusoidal wave and produces pulsating curve jig. The defects of the same rising and falling water flow and action time enhance the loose degree of the bed, alleviate the inhalation effect, make the heavy ore particles in the minerals fully settle, and greatly improve the separation ratio and recovery rate of the equipment. Compared with the sine wave jig, it increases respectively: Sn 3.01%, W 5.5%, Pb 1.63%, Zn 2.04%; water consumption reduces by 30%-40%, occupied area reduces by 1/3, and stroke can be adjusted. Because of the use of electromagnetic adjusting motor to drive, the impulse can be steplessly adjusted. Its performance has reached the advanced level in China, and it is one of the ideal energy-saving gravity separation equipment at present.

Company show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!