Product Description

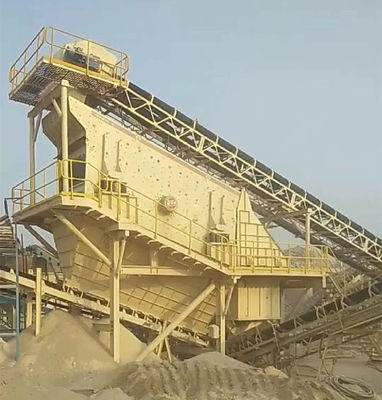

Linear vibrating screen for ore plant

The vibration screen trajectory movement of the circular elliptical. It is a multi-layer, high-efficiency new type vibrating screen designed specifically for quarry screening stones. Widely used in mining, coal, smelting, building materials, refractories, light industry, chemical and other industries of product classification.

ZSW series of linear vibrating screen is widely applied to the screening of dry materials in ore dressing, building material, water and power and light industry.

Features:

- Simple structure; it is easy to replace the screen

- High wear resistance, low noise

- High screening efficiency, low energy consumption

Features and Advantages of LK Series Linear Vibrating

1. High vibrating force with unique eccentric structure. The adopt advanced structure makes the vibrating force powerful;

2. The beam and case of the screen are connected with high strength bolts without welding;

3. Simple structure, easy to repair;

4. Adopting tire coupling and soft connection ensures operation smooth;

5. High efficiency, easy maintenance and sturdy and durable use.

Working Principle of Linear Vibrating Screen

Linear vibrating screen adopts dual motor drive. When the motors do synchronous and reverse rotation, the exciting forces generated by eccentric block cancel each other out on the parallel direction of motor axis, and stack together with the direction that perpendicular to the motor axis, so its trajectory is a straight line. There is a dip on the two motor's relative screen surface, materials are tossed by leaps and bounds forward for linear motion under the exciting force and the self-gravity of the materials so as to achieve the purpose of screening and grading.

Technical Parameters of Linear Vibrating Screen

| Model |

Sieve specifi- cations |

Sieve layer |

Mesh size |

Feeding size |

Proce ssing capacity |

Motor power |

Total weight |

Vibra tion freq uency |

Double ampl- itude |

Obli quity of sieve |

Dimensions |

| (L*W)(mm) |

Layer |

mm |

mm |

(t/h) |

kw |

kg |

(Hz) |

(mm) |

°C |

(L*W*H)(mm) |

| ZSSW1237 |

3700*1200 |

1 |

4-50 |

≤200 |

10-100 |

5.5*2 |

2250 |

16 |

6-8 |

15 |

3800*2050*1920 |

| 2ZSW1237 |

3700*1200 |

2 |

4-50 |

≤200 |

10-100 |

5.5*2 |

3345 |

16 |

6-8 |

15 |

3800*2050*2200 |

| ZSW1443 |

4300*1400 |

1 |

4-50 |

≤200 |

10-150 |

5.5*2 |

4100 |

16 |

6-8 |

15 |

4500*3040*2500 |

| 2ZSW1443 |

4300*1400 |

2 |

4-50 |

≤200 |

10-150 |

5.5*2 |

4900 |

16 |

6-8 |

15 |

4500*3040*2700 |

| 3ZSW1443 |

4300*1400 |

3 |

4-50 |

≤200 |

10-150 |

5.5*2 |

5870 |

16 |

6-8 |

15 |

4500*3040*2820 |

| 2ZSW1548 |

4800*1500 |

2 |

5-50 |

≤200 |

15-200 |

7.5*2 |

5836 |

16 |

8-10 |

15 |

4800*3140*2814 |

| 3ZSW1548 |

4800*1500 |

3 |

5-50 |

≤200 |

15-200 |

7.5*2 |

6900 |

16 |

8-10 |

15 |

4799*3140*3014 |

| 2ZSW1848 |

4800*1800 |

2 |

5-50 |

≤300 |

50-500 |

7.5*2 |

6489 |

16 |

8-10 |

15 |

4799*3440*2814 |

| 3ZSW1848 |

4800*1800 |

3 |

5-50 |

≤300 |

50-500 |

7.5*2 |

7750 |

16 |

8-10 |

15 |

4799*3440*3014 |

| 4ZSW1848 |

4800*1800 |

4 |

5-50 |

≤200 |

50-500 |

11*2 |

8300 |

16 |

8-10 |

15 |

4799*3440*3503 |

| 2ZSW1860 |

6000*1800 |

2 |

5-150 |

≤300 |

80-600 |

11*2 |

9950 |

16 |

8-10 |

15 |

6000*3440*3326 |

CITICIC began in 1956-The largest mining equipment and cement equipment manufacturers in China.CITICIC is a global supplier of technology and services to customers in the process industries,including

Mining,Construction,Metallurgical,Environmental,Power,Chemical,Marine,Casting&Forgings.

CITIC IC produces over 200,000 tons of quality equipment annually. Our products include grinding mills, scrubbers,crushers, kilns, coolers, hoists, reducers, steam turbines and compressors. CITIC IC also manufactures heavy castings and forgings, as well as electric/hydraulic control and lubrication systems.

Our factory in Luoyang covers more than 3 million square meters, of which 2 million square meters is under cover. It has a total workforce of approximately 10,000 employees of which more than 1,200 are engineers.

CITIC HIC produces over 200,000 tons of quality equipment annually. Our products include grinding mills, scrubbers,crushers, kilns, coolers, hoists, reducers, steam turbines and compressors. CITIC HIC also manufactures heavy castings and forgings, as well as electric/hydraulic control and lubrication systems Etc.

|

Machining Equipment

|

Fabrication Equipment

|

|

Casting & Forging Equipment

|

Heat treatment Equipment

|

FAQ

Quality Control

Physical & Chemical Identification Center

CITICIC owns a professional testing and metrology institute which provides advanced testing methods such as nondestructive testing, industrial chemical analysis, metallographic testing and analysis, mechanical testing, sample preparation, meter/length measurement, weighing apparatus verification, and weighman inspection. Our metrology institute has taken a leading role in China.

CITICIC owns nearly two hundred types of advanced testing equipment, nine different measurement standards and nearly twenty types of world-class testing equipment which have been imported from international locations such as Germany, Japan, USA, UK and Belgium.

Our Services

Aftersales service

CITIC Heavy Industries is your business partner in the After Market.

CITICIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

CITIC’s Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

CITICIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!