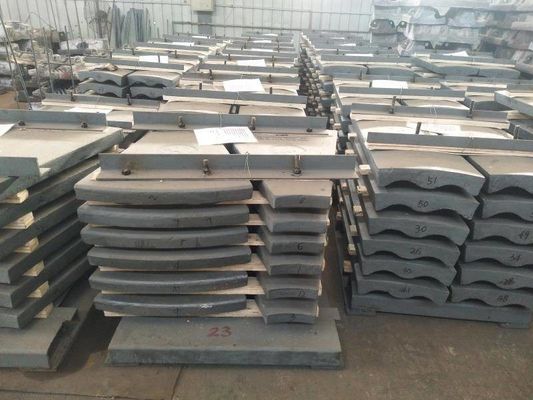

Ball mill / AG mill liner

Liner plate is used to protect the cylinder body from direct impact and friction of abrasive body and material. At the same time, different forms of lining plate can be used to adjust the movement state of abrasive body, so as to enhance the grinding effect of abrasive body on material, which is helpful to improve grinding efficiency of mill, increase output and reduce metal consumption.

China's current general wear resistant material series of high manganese steel series: such as high manganese steel (ZGMN13),

High manganese alloy (Zgmn13Cr2MoR), ultra-high manganese alloy (Zgmn18Cr2MoR), etc.

High manganese steel (such as ZGMN13) under severe impact or contact stress, its surface will rapidly harden, while the core still maintains a strong toughness, hard outside and tough inside both wear resistance and impact resistance.And the heavier the impact on the surface, the more full the surface hardening, the better the wear resistance.Because the hardness of high manganese steel itself is very low (HB170-230), the wear resistance is extremely limited before hardening. If the surface of high manganese steel is not enough to bear the impact force, the surface can not be fully hardened (after full hardening, the surface hardness can reach HB550 or below, otherwise), then the wear resistance will not play a role, and the wear resistance will not be shown.

Because Zgmn18Cr2 contains more manganese, the surface hardening can be more sufficient, so more wear-resistant.

Of course, ZGMN18Cr2 series (such as ZGMN18Cr2MORE) is also more expensive than ZGMN13 series.

The main material in the hammer of high manganese steel is high manganese steel (Mn13,Mn13Cr2 and Mn18Cr2). With the continuous development of wear-resistant materials, the high toughness of high manganese steel is incomparable to other wear-resistant materials

Features:

Material: High Manganese Steel, Super-High Manganese Steel, High Chromium Casting Iron, Alloy Steel, Chromium-molybdenum Steel, Low Carbon Steel, or as per the customer requests.

Hardness: as per your request.

Impact Value: as per your request.

Tensile Strength: as per your request.

Heat Treatment Process: Normalizing, Tempering, Quenching & Tempering.

Surface treatment: rust preventive oil, or as per your requests.

Process: raw material purchasing - casting- rough machining - heat treatment - semi-machining - finish machining - painting and packing. Various process conditions are available.

Standard: ANSI, API, ASTM, BSI, DIN, GB, ISO, JIS.

QA and DOC: Chemical Composition Report, Mechanical Properties Report, SpheroidizatioRate Report, UT Report, PT Report, Heat Treatment Report, Dimensions Check Report, Hardness Report and etc.

Quality Control: UT Test, MT Test, Visual Inspection, Third Party Inspection, Customer On-site Inspection.

Chemical composition |

Maximum percent allowable |

| Carbon |

0.24% ( 0.28%)

(0.28% for head and trunnion) |

| Manganese |

0.90% |

| Silicon |

0.30-0.45% |

| Sulfur |

0.025% |

| Phosphorus |

0.025% |

| Nickel |

0.25% |

| Chromium |

0.20% |

| Molybdenum |

0.15% |

| Cooper |

0.20% |

| Vanadium |

0.03% |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!