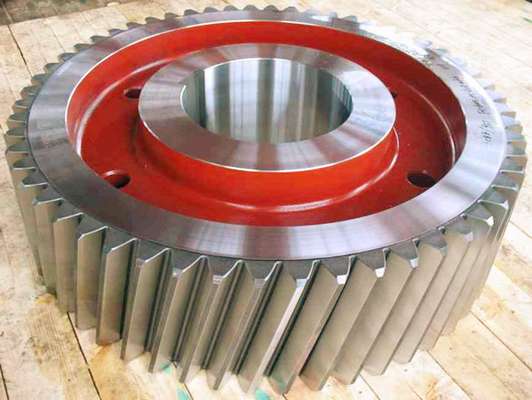

Rotary kilns, ball mills, rotary dryers custom casting and forging pinion gear

Main material: ZG45, ZG42CrMO

Applicable equipment: rotary kiln, ball mill

Suitable for industries: cement, electric power, metallurgy, chemical, non-metal mining and other industries

Big gear, also known as big gear ring, is the key component of rotary kiln, ball mill and other equipment. Among them, the big gear ring of rotary kiln is one of the most critical parts in the transmission device of rotary kiln. Its installation quality directly affects the stability of the transmission system of rotary kiln, the stability of the operation of rotary kiln, the service life of kiln lining and the operation rate of rotary kiln.

Due to the requirements of manufacturing capacity, transportation and installation, the ring consists of two half gears connected together with opposite screws and tangentially fixed to the kiln body by a spring plate. In order to complete the installation and alignment of large gear ring with high quality, scientific and feasible construction schemes must be formulated whether it is newly installed or reinstalled after overhaul

Gear performance characteristics:

1. High bearing capacity and smooth operation

The helical gear has the characteristics of high bearing capacity, smooth operation and low noise.

2. Gear production technology is advanced and stiffness performance is superior

The gear is made of ZG45 or ZG42CrMO alloy cast steel with heat treatment hardness OF HB260 ~ 300. Adopting carburizing quenching grinding process, the hardness of tooth surface is HRC57 ~ 61. The other big gear for the two half split structure, tooth width using Y structure, to ensure good rigidity of gear.

3. Simple structure, easy to manufacture and daily maintenance

Both sides of big gear flange are machined, both can match with cylinder flange, and can be used by turning around. Pinion and shaft are forged as a whole, both ends of shaft are symmetrical, both milling has keyway, can also be used for turning.

Production strength:

1, the strength of large-scale cast steel manufacturing equipment, to ensure the product quality and production cycle.

2, perfect hot processing production technology to ensure the inner quality of key parts.

3, advanced flaw detector, universal strength testing machine and other testing equipment, to ensure the quality of products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!