A Wide Range Of Vertical Mill Accessories Castings And Forgings

1. Introduction of vertical mill

Suitable for enterprise type: cement plant, mill station, steel plant, etc.

Steel slag vertical mill integrates crushing, conveying, grinding and drying. It is a new type of environmental protection and efficient, and is the most ideal production equipment of steel slag micro powder at present. The grinding efficiency of the vertical steel slag mill is high, the power consumption of the system is not more than 50kWh/t, the specific surface area of the steel slag powder can reach 4500~5000 cm2/g, and the performance is superior.

2. Working principle of vertical mill

The material feeding tube falls into the center of the mill plate, the mill plate rotating at constant speed is evenly dispersed and paved with the help of centrifugal force, so that the material can form a certain thickness of the bed, and the material is rolled by multiple rollers on the mill plate at the same time, and is crushed. Under the continuous drive of centrifugal force, the material keeps moving to the outer edge of the mill. The material leaving the mill meets the hot gas entering the mill through the air ring and then rises, and enters the separator through the shell in the middle of the mill. In this process, the material and the hot gas have a full heat exchange, and the water is quickly evaporated. The separator controls the fineness of the finished product at the exit of the roller mill. Particles larger than the specified size are separated and fall back to the grinding plate. Materials that meet the fineness requirements enter the finished product through the selection machine.

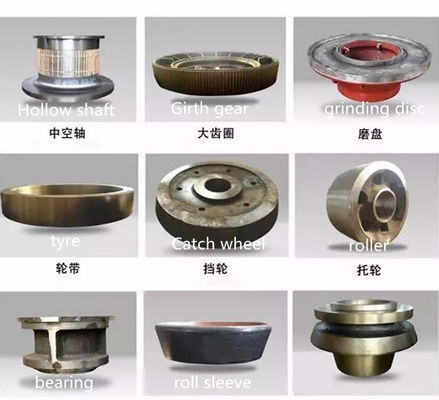

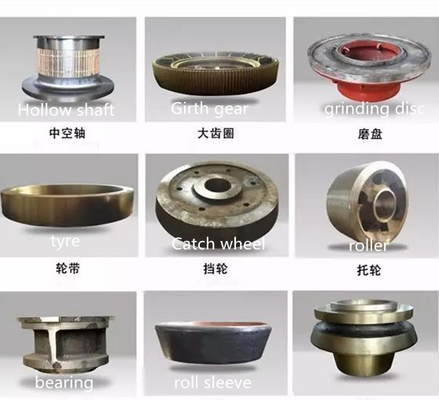

3.Castings and forgings of table of vertical mill accessories

| Vertical mill machine |

The name of the accessories |

Note |

| Roller department |

Roller plate, roller, pressure plate, sleeve, sealing ring, roller bearing cover, wear-resisting, distance ring, roller stents, roller plate, O ring, the axis of rotation sealing, roller bearing, stud, magnetic plug, connection board, hinge bearings, roller, grinding roller, pointer, bolt (pin) framework, heat resistance, pressure plate |

|

| The ministry of mill |

Grinding plate lining, air guide cone, scraper, nozzle ring, nozzle ring, cover plate, grinding plate seat, grinding plate cover, labyrinth seal |

|

| Frame body |

Tensioning rod frame, sealing device, lining plate, wear plate |

|

| The ministry of separator |

Fixed blade, rotary blade, drive shaft, housing, coupling, thrust bearing, aligning bearing, skeleton oil seal, O-ring seal, separator spindle, motor, reducer |

|

| Tensioning device |

Pin shaft, thickness gauge, ball socket, shaft sleeve, tensioning rod, hinged seat, steel ball, support, hydraulic cylinder assembly, accumulator |

|

| The seal line |

Centripetal joint bearing, elbow, sealed air pipe, flange, bushing |

|

| Maintenance and repair equipment |

Roller support, hydraulic station, maintenance tools, one-way throttle valve |

|

| Three gate |

Roller support, hydraulic station, maintenance tools, one-way throttle valve |

|

A Wide Range Of Vertical Mill Accessories Castings And Forgings

Depending on our company's strong scientific research ability and production and sales ability, relying on advanced and mature production technology in Luoyang mining machinery industry cluster area, we have cooperated with major well-known enterprises at home and abroad to provide technical services and complete sets of equipment for key projects in national mining, metallurgy, building materials, lifting, electric power, non-ferrous metals, environmental protection, chemical industry, petroleum and other industries. Spare parts. Relying on innovative technology, new products and perfect after-sales service, the company has won the trust and support of more and more domestic and foreign customers.

After-sales service

LUOYANG ZHONGTAI INDUSTRIES able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

LUOYANG ZHONGTAI INDUSTRIES’s Field Service Engineers are trained specifically in the LUOYANG ZHONGTAI INDUSTRIES brand group products but are capable of undertaking the servicing of other OEM brands. Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time. LUOYANG ZHONGTAI INDUSTRIES also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!