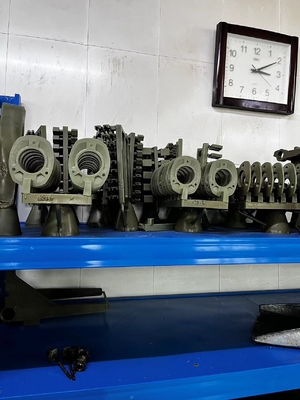

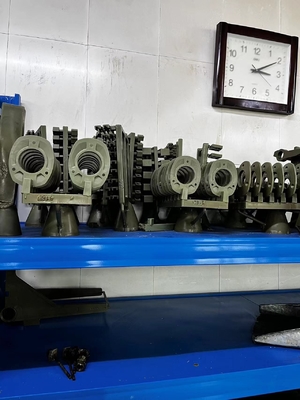

Precision Metal Steel Cast Iron Aluminum Lost Wax Vacuum Investment Casting Parts

1. Investment casting, also known as lost wax casting, wax casting or precision investment casting, is a casting process for manufacturing complex shapes and high-precision parts. The process typically includes the following steps:

(1) Mold manufacturing: First make molds according to product design requirements. Molds can be made of metal materials (such as aluminum alloy, steel, etc.) or refractory materials (such as gypsum, ceramics, etc.). Molds are used to make wax molds.

(2) Wax mold injection mold: melted wax material is injected into the mold to fill the mold cavity and form a wax mold similar to the final product.

(3) Wax mold assembly: a number of wax molds are assembled together to form a complete mold assembly, including feeding system, pouring system, etc.

(4) Vacuum dewaxing: the wax mold is placed in the vacuum dewaxing equipment, and the wax material in the wax mold is melted and evaporated by heating and vacuuming, so that the internal cavity of the wax mold becomes a cavity.

(5) Smelting metal: smelting appropriate metal alloys, usually using electric arc furnaces, induction furnaces or argon arc furnaces and other equipment for smelting.

(6) Casting injection: the preheated mold assembly is placed in the casting equipment, and the molten metal is injected into the mold cavity to fill the entire internal cavity of the wax mold.

(7) Cooling curing: After the metal is cooled and cured, the mold assembly is removed from the casting equipment.

(8) Mold crushing: the cooling solidified metal parts are separated from the mold, and the mold is often broken by mechanical or chemical methods to obtain the final casting.

(9) Finishing processing: finishing, removing residual material, deburring and other processing processes on the casting to obtain the final product that meets the requirements.

Investment casting process is suitable for the manufacture of complex, high-precision, high-quality parts, commonly used in aerospace, aviation engines, automobiles, medical equipment, electronics and other fields. It enables the production of parts with complex shapes, small structures and precise dimensions.

Precision Metal Steel Cast Iron Aluminum Lost Wax Vacuum Investment Casting Parts

Castings And Forgings

2. Table examples of common parameters of die casting products:

|

Product type

|

Size range

|

Commonly used material

|

Advantage

|

|

Part A

|

10-500 mm

|

Steel, stainless steel, aluminum alloy, nickel-based alloy, titanium alloy

|

High precision, complex shape, excellent surface quality

|

|

Part B

|

50-300 mm

|

Iron, copper alloy, nickel-based alloy, titanium alloy

|

High strength, wear resistance, corrosion resistance

|

|

Part C

|

20-200 mm

|

Copper alloy, nickel-based alloy, titanium alloy

|

Thin-wall structure, high temperature performance, good dimensional consistency

|

|

Part D

|

30-400 mm

|

Aluminum alloy, nickel-based alloy, titanium alloy

|

Light weight, good mechanical properties, heat treatment controllable

|

|

Part E

|

10-150 mm

|

Copper alloy, aluminum alloy, nickel-based alloy

|

Sealing performance, magnetic requirements, good heat resistance

|

Precision Metal Steel Cast Iron Aluminum Lost Wax Vacuum Investment Casting Parts

Castings And Forgings

After-sales service

LUOYANG ZHONGTAI INDUSTRIES able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

LUOYANG ZHONGTAI INDUSTRIES’s Field Service Engineers are trained specifically in the LUOYANG ZHONGTAI INDUSTRIES brand group products but are capable of undertaking the servicing of other OEM brands. Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time. LUOYANG ZHONGTAI INDUSTRIES also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!