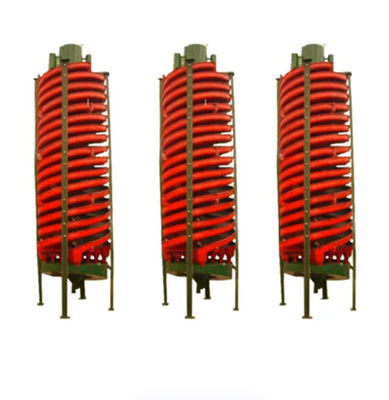

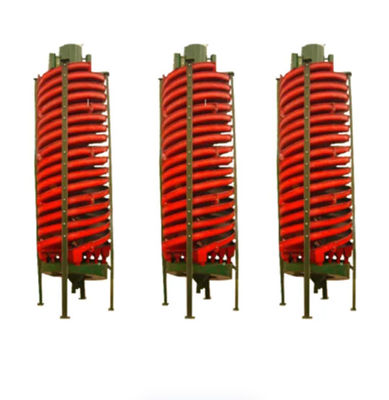

Special Spiral Chute For Gravity Separation Of Fine-Grained Minerals

Scope of application

It is suitable for the separation of fine particles of iron, tin, tungsten, tantalum, niobium, gold, coal, monazite, rutile, zircon and other metallic and non-metallic minerals with sufficient specific gravity, ranging from 0.3 to 0.02 millimeters.

Working principle

The ore separator is freely placed on the cross (or tripod) of the support table. Uniform pulp is slowly fed to the surface of the spiral trough through the feeding trough installed at the first end of the spiral trough for separation. The tail end of the spiral groove is equipped with a valve block-type product cutting groove, which divides the sorted products into three (or four) types along the radial direction according to the grade. The cut-off width of each product is changed by adjusting the position of the valve block. The product aggregation hopper is a concentric annular cylinder that separately collects and discharges the multiple ore flows that have been intercepted. The cross-section of the spiral chute and the slope change of the curve are particularly suitable for the separation of fine particle materials. This mineral processing equipment features a simple structure, no moving parts, light weight, no noise, and is convenient for configuration, installation and maintenance.

Structural Characteristics

The FRP spiral chute is composed of six parts: the ore feeding and distribution device, the ore feeding chute, the spiral chute, the product interception chute, the product aggregation hopper and the chute support (including the cross or tripod). The helical groove formed by the connection of helical plates is the main component. The spiral plates are made of fiberglass reinforced plastic (FRP) and are connected together by bolts. There is a prefabricated wear-resistant layer on the separation surface of the spiral groove. This mineral processing equipment has the advantages of being lightweight, sturdy and durable. A multi-tube ore feeder and distributor is installed above the spiral groove, ensuring uniform ore distribution and simple control.

Paramenters

| model |

5LL-1500 |

5LL-1200 |

5LL-900 |

5LL-600 |

5LL-400 |

| External diameter(mm) |

1500 |

1200 |

900 |

600 |

400 |

| Screw pitch(mm) |

540,720 |

900,720,540 |

675,540,405 |

450,360,270 |

240,180 |

| Ratio of screw pitch to diameter |

0.75,0.6,0.45 |

0.75,0.6,0.45 |

0.75,0.6,0.45 |

0.75,0.6,0.45 |

0.6,0.45 |

| Horizontal Angle(°) |

9° |

9° |

9° |

9° |

9° |

| Spiral head number |

4-2 |

4 |

4 |

4 |

4 |

| Feeding Particle Size (mm) |

0.3-0.02 |

0.3-0.03 |

0.3-0.03 |

0.2-0.02 |

0.2-0.02 |

| Feeding concentration(%) |

25-55 |

25-55 |

25-55 |

25-55 |

25-55 |

| Processing Capacity (ton/hour) |

8-16 |

4-6 |

2-3 |

0.8-1.2 |

0.15-0.2 |

| Overall dimension |

length(mm) |

1560 |

1360 |

1060 |

700 |

460 |

| width(mm) |

1560 |

1360 |

1060 |

700 |

460 |

| height(mm) |

5230 |

5230 |

4000 |

26000 |

1500 |

| weight(KG) |

800 |

600 |

400 |

150 |

50 |

Ore Dressing Equipment

Ore Dressing Equipment

Ore Dressing Equipment

Q&A

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time?

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms?

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!