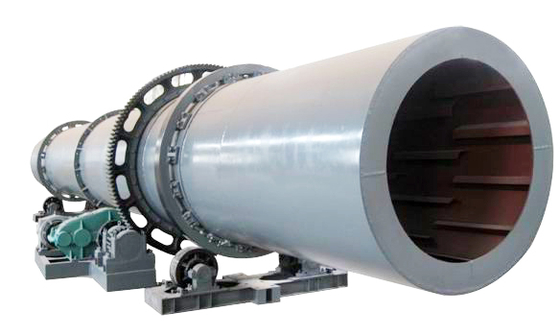

Rotary Dryer With Strong Adaptability And Good Uniformity Of Dried Products

Rotary dryer is used to burn the hard magnetic ferrite powder; it can also be used in cement, metallurgy, chemical industry. The equipment is composed of the main kiln and its supporting transmission, cooling pipe, fuel system, electrical control, the second wind devices, exhaust dust removal device and preheating kiln body. It has the over temperature alarm, overload alarm, work automatic temperature control, and kiln oxygen adjustable functions.

Rotary Dryer Working principle

Wet material is input from one end of the dryer, under the copy board flip of the inner cylinder cloth, material is uniformly distributed and dispersed in the dryer, and fully contacts with the hot air stream (countercurrent) to speed up the drying heat transfer, and mass transfer driving force. During the drying process, the material in the copy board and the hot gas stream with the inclination of the role, it can regulate movement to another section star-like discharge valve to discharge the finished products.

Structural composition

It is mainly composed of a rotating cylinder, rakes, transmission devices, sealing structures, heating systems, etc.

Applications

- It is applied to the dry chemical, mining, metallurgy and other industries’ large particles than significant materials.Such as: ore, blast furnace slag, coal, metal powder, phosphate, ammonium sulfate.

- To the powder have the special requirements like: Foaming agent, lees residue, precipitated calcium carbonate, activated clay, magnetic powder, graphite, dregs.

Feature

- Require the low-temperature drying, and requires large quantities of continuous dry material.

- Rotary dryer has high degree of mechanization, large production capacity.

- Fluid through the cylinder the resistance is small, consumption function is low.

- The strong adaptability to the material properties.

- Stable operation, low operating costs and good dried product uniformity.

Product parameters Of Cement Rotary Kiln

H series rotary dryer technical parameters, tumble dryer, drum dryer, rotary dryer

| Product SPEC(m) |

Drum volume(m³) |

Production capacity(t/h) |

Installation Angle(%) |

Maximum intake temperature

(℃)

|

Main motor power(kw) |

Total

weight(t)

|

| Φ1.2×8.0 |

9.0 |

1.9-2.4 |

3-5 |

700-800 |

7.5 |

9 |

| Φ1.2×10 |

11.3 |

2.4-3.0 |

3-5 |

700-800 |

7.5 |

11 |

| Φ1.5×12 |

21.2 |

4.5-5.7 |

3-5 |

700-800 |

15 |

18.5 |

| Φ1.5×14 |

24.7 |

5.3-6.6 |

3-5 |

700-800 |

15 |

19.7 |

| Φ1.5×15 |

26.5 |

5.7-7.1 |

3-5 |

700-800 |

15 |

20.5 |

| Φ1.8×12 |

30.5 |

6.5-8.1 |

3-5 |

700-800 |

18.5 |

21.5 |

| Φ1.8×14 |

35.6 |

7.6-9.5 |

3-5 |

700-800 |

18.5 |

23 |

| Φ2.2×12 |

45.6 |

9.7-12.2 |

3-5 |

700-800 |

22 |

33.5 |

| Φ2.2×14 |

53.2 |

11.4-14.2 |

3-5 |

700-800 |

22 |

36 |

| Φ2.2×16 |

60.8 |

13.0-16.2 |

3-5 |

700-800 |

22 |

38 |

| Φ2.4×14 |

63.3 |

13.5-16.9 |

3-5 |

700-800 |

37 |

45 |

| Φ2.4×18 |

81.4 |

17.4-21.7 |

3-5 |

700-800 |

37 |

49 |

| Φ2.4×20 |

90.4 |

19.3-24.1 |

3-5 |

700-800 |

45 |

54 |

| Φ2.4×22 |

99.5 |

21.2-26.5 |

3-5 |

700-800 |

45 |

58 |

| Φ2.6×24 |

127.4 |

27.4-34.0 |

3-5 |

700-800 |

55 |

73 |

| Φ3.0×20 |

141.3 |

30.1-37.7 |

3-5 |

700-800 |

75 |

85 |

| Φ3.0×25 |

176.6 |

37.7-47.1 |

3-5 |

700-800 |

75 |

95 |

| Φ3.2×25 |

201 |

42.9-53.6 |

3-5 |

700-800 |

90 |

110 |

| Φ3.6×28 |

285 |

60.8-76.0 |

3-5 |

700-800 |

160 |

135 |

Product Display Of Cement Rotary Kiln

Cement Rotary Kiln

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time:

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms:

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!