Energy-Saving And Reliable Jaw Crusher With Uniform Particle Size

Introduction

The jaw crusher, commonly known as the jaw breaker or tiger mouth, is a crushing machine that simulates the movement of animal jaws to crush materials.With features of high crushing ratio, uniform product granularity, reasonable structure, reliable operation, convenient maintenance, and economical operation costs, it can crush various materials with compressive strength not exceeding 320 MPa.

Scope of application

Jaw crushers are mainly used for medium-sized crushing of various ores and large materials. Jaw crushers are widely used in mining, metallurgy, building materials, highways, railways, water conservancy, and chemical industries. The maximum compressive strength of crushed materials is 320Mpa.

Working Principle

The jaw crusher is mainly composed of a frame, eccentric shaft, large pulley, flywheel, side guard plate, elbow plate, elbow plate rear seat, gap adjustment screw, return spring, fixed jaw plate and movable jaw plate.Its crushing mechanism is characterized by a gyratory compression method. During operation, the motor drives the belt and pulley, which in turn causes the movable jaw to move up and down through the eccentric shaft. When the movable jaw rises, the angle between the elbow plate and the movable jaw increases, pushing the movable jaw plate towards the fixed jaw plate. The materials are crushed multiple times through compression, grinding, and rubbing between the two jaw plates. When the movable jaw descends, the angle between the elbow plate and the movable jaw decreases, and the movable jaw plate moves away from the fixed jaw plate under the action of the tension rod and spring. The crushed materials are discharged freely through the outlet at the bottom of the jaw cavity under the force of gravity.As the motor rotates continuously, the movable jaw performs periodic crushing and discharging, achieving batch production.

Advantages and Features

- The deep crushing cavity with no dead zone improves feeding capacity and output.

- With a large crushing ratio, it produces uniform particle size.

- The gasket-type discharge opening adjustment device is reliable, convenient, and has a wide adjustment range, increasing equipment flexibility.

- The lubrication system is safe and reliable, with easy component replacement and minimal maintenance workload.

- Simple structure, reliable operation, and low operating costs.

- Energy-saving: 15%-30% energy savings for single machine, over double for system.

- Large discharge opening adjustment range to meet different user requirements.

- Low noise and minimal dust emission.

Product Parameters Of Stone Crusher Machine

| Model |

Feeding port size

(mm) |

Feed size Max

(mm) |

Discharge range opening

(mm) |

Processing capacity

(t/h) |

Eccentric shaft speed

(r/min) |

Motor power

(kw) |

Total weight

(t) |

Dimensions

(L×W×H)

(mm) |

| PE-150×250 |

150×250 |

125 |

10-40 |

1-3 |

250 |

5.5 |

0.8 |

720×660×850 |

| PE-200×300 |

200×300 |

180 |

15-50 |

2-6 |

260 |

7.5 |

1.2 |

910×750×990 |

| PE-200×350 |

200×350 |

180 |

18-70 |

3-10 |

260 |

11 |

1.5 |

1000×870×990 |

| PE-250×400 |

250×400 |

210 |

20-60 |

5-20 |

300 |

15 |

2.8 |

1300×1090×1270 |

| PE-400×600 |

400×600 |

340 |

40-100 |

16-60 |

275 |

30 |

7 |

1730×1730×1630 |

| PE-500×750 |

500×750 |

425 |

50-100 |

40-110 |

275 |

55 |

12 |

1980×2080×1870 |

| PE-600×750 |

600×750 |

500 |

150-200 |

80-240 |

275 |

55 |

15.8 |

2070×2000×1920 |

| PE-600×900 |

600×900 |

500 |

65-160 |

50-180 |

250 |

55 |

17 |

2190×2206×2300 |

| PE-750×1060 |

750×1060 |

630 |

80-140 |

110-320 |

250 |

110 |

29 |

2660×2430×2800 |

| PE-800×1060 |

800×1060 |

640 |

130-190 |

130-330 |

250 |

110 |

29.8 |

2710×2430×2800 |

| PE-830×1060 |

830×1060 |

650 |

160-220 |

150-336 |

250 |

110 |

30.7 |

2740×2430×2800 |

| PE-870×1060 |

870×1060 |

660 |

200-260 |

190-336 |

250 |

110 |

31.5 |

2810×2430×2800 |

| PE-900×1060 |

900×1060 |

685 |

230-290 |

230-390 |

250 |

110 |

33 |

2870×2420×2940 |

| PE-900×1200 |

900×1200 |

750 |

95-165 |

220-450 |

200 |

110 |

52 |

3380×2870×3330 |

| PE-1000×1200 |

1000×1200 |

850 |

195-265 |

315-500 |

200 |

110 |

55 |

3480×2876×3330 |

| PE-1200×1500 |

1200×1500 |

1020 |

150-350 |

400-800 |

180 |

160-220 |

100.9 |

4200×3300×3500 |

| PE-1500×1800 |

1500×1800 |

1200 |

220-350 |

500-1000 |

180 |

280-355 |

122 |

5160×3660×4248 |

| PE-1600×2100 |

1600×2100 |

1500 |

300-400 |

1300-2200 |

160 |

350-380 |

150.6 |

6210×4013×4716 |

| PEX-150×750 |

150×750 |

120 |

18-48 |

8-25 |

320 |

15 |

3.8 |

1200×1530×1060 |

| PEX-250×750 |

250×750 |

210 |

25-60 |

13-35 |

330 |

30 |

5.5 |

1380×1750×1540 |

| PEX-250×1000 |

250×1000 |

210 |

25-60 |

16-52 |

330 |

30 |

7 |

1560×1950×1390 |

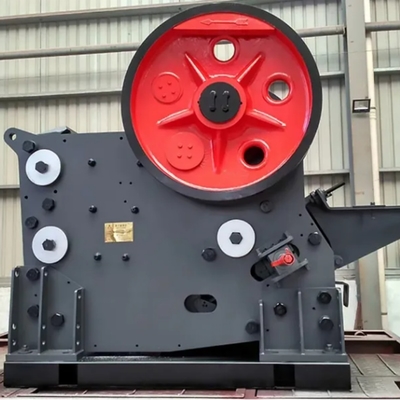

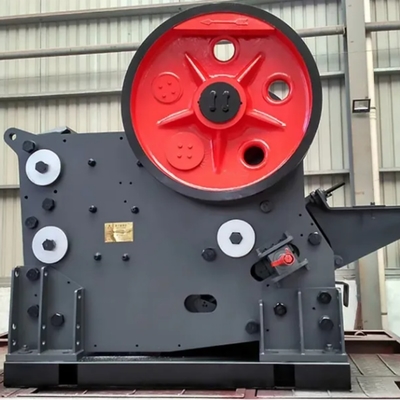

Product Display Of Stone Crusher Machine

Stone Crusher Machine

Stone Crusher Machine

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time:

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms:

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!