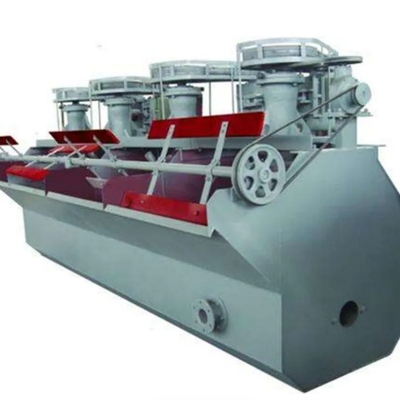

Flexible Process Flow Convenient And Reliable Operation Flotation Machine

Flotation machine is a mechanical equipment that completes the flotation process, mainly used to separate non-ferrous metals, ferrous metals and non-metallic minerals.

Working Principle

The flotation machine's electric motor drives the impeller, creating a centrifugal force and negative pressure. This draws in air and mixes it with the slurry. Simultaneously, the slurry is agitated and mixed with the reagents, creating a finer foam. Minerals adhere to the foam and float to the surface of the slurry, forming a mineralized foam. This is then scraped off by a scraper, achieving mineral separation.

Performance Characteristics

The structure of flotation machine: this machine is mainly composed of pulp chute, mixing device, air charging system, mineralized bubble discharging device and electro motor.

(1) Pulp chute: It has pulp feeding mouth and the gate device used for adjusting the liquid level and it is mainly composed of mainly composed by the chute body which is melt by the steel board and gate melt by the steel board and steel rod.

(2) Mixing device: It is mainly used for mixing the pulp in order to prevent the mineral sand to deposit on the chute, and it is mainly composed by the belt wheel, impeller, vertical shaft and the impeller is made of the anti-abrasion rubber.

(3) Air charging system: It is mainly composed by the inlet air pipe. When the impeller rotates, there will produce negative pressure inside the impeller chamber in order to absorb air through the hollow pump line and disperse the pulp in order to form a bubble group. This kind of pulp with large quantity of bubbles will be thrown to the stator fast by the rotary force of the impeller and further mineralize the bubbles in the pulp, and the rotary movement that is meant to eliminate the pulp flow in the flotation cell will cause large quantity of microvesicle and provide necessary condition for the flotation process.

(4) Mineralized foam discharging device: This device is mainly used for scarping the foam floating on the cell and it is mainly composed by the reducer driven by the electric motor and scrapper driven by the reducer.

Technical parameters of Ore Dressing Equipment

SF Flotation Machine

| Model |

SF0.37 |

SF0.7 |

SF1.2 |

SF2.8 |

SF4 |

SF8 |

| Trough capacity(m3) |

0.37 |

0.7 |

1.2 |

2.8 |

4 |

8 |

| Impeller diameter(mm) |

300 |

350 |

450 |

550 |

650 |

760 |

| Production capacity (m3/min) |

0.2-0.4 |

0.3-0.9 |

0.6-1.2 |

1.5-3.5 |

0.5-4 |

4-8 |

| Impeller rotation speed (r/min) |

352 |

400 |

312 |

268 |

238 |

191 |

| Motor |

Model |

①Y90L-4 |

①Y100L2-4 |

①Y132M2-6 |

①Y160L-6 |

①Y180L-6 |

①Y250M-8 |

| ②Y90S-4 |

②Y90S-4 |

②Y90S-4 |

②Y90S-4 |

②Y90L-4 |

②Y100L-6 |

| Power(kw) |

①1.5 |

①3 |

①5.5 |

①11 |

①15 |

①30 |

| ②1.1 |

②1.1 |

②1.1 |

②1.1 |

②1.5 |

②1.5 |

| Dimensions(mm) |

700×700×750 |

900×820×950 |

1100×1100×1100 |

1700×1600×1150 |

1850×2050×1200 |

2200×2900×1400 |

| Single trough weight(kg) |

468 |

600 |

1373 |

2338 |

2660 |

4486 |

Product Display Of Ore Dressing Equipment

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time:

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms:

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!