Good Sorting Efficiency Simple Operation Low Energy Consumption Ore Shaking Table

Ore dressing shaker is a gravity ore dressing equipment commonly used for fine-grained ore sorting.

Working Principle

Shaking bed ore treatment uses the combined effect of mechanical reciprocating motion of the inclined bed surface and thin-layer inclined water flow to make the ore particles loosely layer and belt on the bed surface, thereby realizing the separation by density.

Scope of application

This ore dressing equipment is mainly used to select non-colored and black rare precious metal minerals such as tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, etc., and to select 4-0.02 mm pyrote; appropriately change the bed strip form and select coal and coal sludge; and sort other mixed materials with sufficient specific gravity difference and particle size composition.

Performance characteristics

The shaking table is a combination of the domestic shaker and gravity beneficiation technology, having high concentration ratio, good sorting efficiency, simple operation, etc., and can get final concentrate and final tailings once for all.

Compared with the traditional process, it has the advantage of no pharmacy, low energy consumption and easy management, with high performance and low cost.

Product parameters of ore dressing equipment shaking table

| |

Coarse sand table |

Fine sand table |

Slime (slotted) shaking table |

Fine mud shaking table |

| Feed size/mm |

2~0.5 |

0.5~0.074 |

0.07~0.019 |

0.019~0.0037 |

| Ore feed (tin ore)(t/d) |

20~35 |

10~20 |

3~10 |

5~15 |

|

Mineral surface size

/mm

|

4395×1825 |

4395×1825 |

4395×1825 |

4395×1825 |

|

Mineral surface area

/m2

|

7.4 |

7.4 |

7.4 |

7.4 |

| Stroke Length/mm |

16~22 |

11~16 |

8~11 |

5~7 |

| Times of stroke/min-1 |

270~290 |

290~320 |

320~360 |

480~520 |

|

Transverse slope of table surface(°)

|

2.5~4.5 |

1.5~3.5 |

1~2 |

1~1.15 |

| Power /Kw |

1.1 |

1.1 |

1.1 |

1.1 |

| Dimensions /mm |

5446×1825×1212 |

5446×1825×1227 |

5446×1825×1203 |

5446×2338×1203 |

| Total weight/Kg |

1015 |

1030 |

1065 |

1065 |

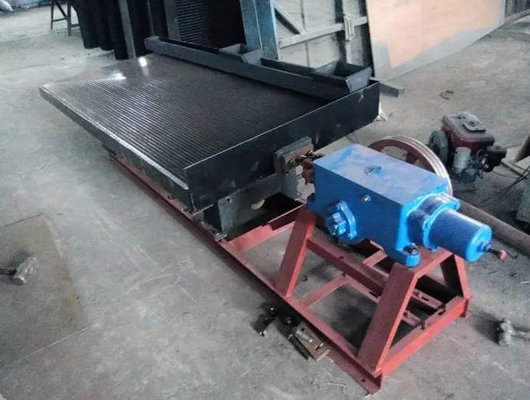

Product Display

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time:

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms:

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!