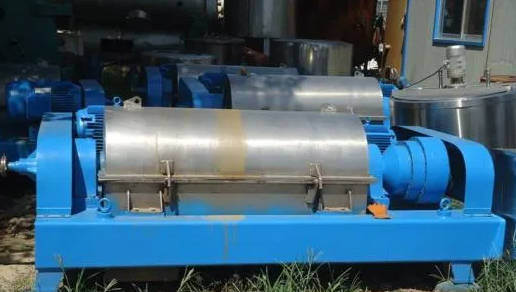

Horizontal Vibrating Centrifuge With Low Product Breakage Minimal Wear On The Sieve Basket

Working Principle

Material is conveyed to the bottom of the screen basket through an enamel-lined feed pipe and screen base. Under centrifugal force, it adheres tightly to the screen surface. Simultaneously, the vibration drive causes the material layer to slide evenly towards the larger end of the screen basket. The dehydrated solid material is thrown out from around the screen basket and smoothly discharged through the discharge port at the bottom of the casing. The water in the material, under centrifugal force, penetrates the material layer and screen gaps, is thrown towards the inner wall of the casing, and flows along the wall to the drain outlet for separation and discharge.

Core Advantages

High processing efficiency, excellent dehydration and separation effect, suitable for large-scale material processing needs;

Low material breakage rate, wear-resistant and durable screen basket, long service life, reducing replacement costs;

Equipped with the TWZ inertial over-resonance vibration system, amplitude and frequency are stable and controllable, resulting in more reliable operation;

The TWZ vibration system features stable operation, low noise, simple structure, convenient maintenance, and energy saving, leading to lower operating costs.

Product parameters of Ore Dressing Equipment

| SPEC |

Unit |

Model |

| TWZ850 |

TWZ10A |

TWZ850 |

TWZ850 |

TWZ850 |

TWZ850 |

| Feed size |

mm |

≤ |

0~25 |

0.5~50 |

0~50 |

≤50 |

0.5~50 |

| Processing power |

t/h |

30~50 |

50~100 |

100~150 |

180~250 |

200~300 |

250~350 |

| Product water |

% |

5~9 |

| Big end diameter of sieve basket |

mm |

850 |

100 |

1150 |

1300 |

1400 |

1500 |

| Seam screen size |

mm |

0.25,0.3,0.35,0.5 |

| Sieve basket vibration frequency |

Hz |

25 |

25 |

25 |

25 |

25 |

25 |

| Double amplitude |

mm |

4~6 |

4~6 |

4~6 |

4~6 |

4~6 |

4~6 |

| Main motor power |

Kw |

15 |

22 |

37.5 |

45 |

55 |

75 |

| Vibration motor power |

Kw |

4 |

5.5 |

7.5 |

7.5 |

11 |

15 |

| Oil pump motor power |

Kw |

0.37 |

0.37 |

0.55 |

0.55 |

0.55 |

0.55 |

| Dimension |

L |

mm |

2060 |

2150 |

2800 |

2700 |

3100 |

3170 |

| W |

mm |

1510 |

1875 |

1930 |

2260 |

3090 |

2975 |

| H |

mm |

1652 |

1765 |

1930 |

2245 |

2295 |

2400 |

| Device weight |

Kg |

2500 |

2620 |

5527 |

6500 |

9200 |

10000 |

Note: The external moisture of the product is related to the nature, particle size composition and handling capacity of the material, but mainly depends on the slime content of the material. -0.5mm particle size content in feeding < 10%, the external moisture of the product is generally 5~9%.

Instructions for Ordering:

(1)Screen gaps can be supplied according to user requirements.

(2)The host set of supply (including motor).

(3)Spare parts will be ordered separately.

Product Display of Ore Dressing Equipment

Ore Dressing Equipment

FQA

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time :

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms :

A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!